Powerline and Gas Pipeline Inspection Using Thermal and LiDAR Drone Technology

Our comprehensive inspection service utilizes advanced drone technology to perform detailed and efficient inspections of powerlines and gas pipelines. Combining thermal imaging with LiDAR scanning, we offer a robust solution for identifying potential issues and ensuring the integrity of critical infrastructure.

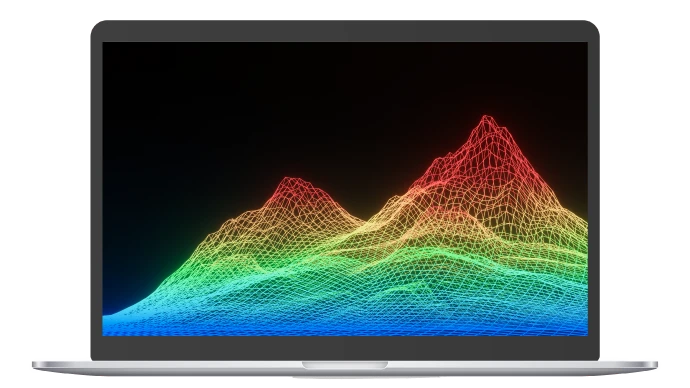

Our Powerline and Gas Pipeline Inspection service uses advanced thermal and LiDAR drone technology to provide detailed, high-resolution assessments. Thermal drones detect heat anomalies and potential issues in real-time, while LiDAR scans deliver precise 3D mapping and structural insights. This combined approach ensures early problem detection, accurate measurements, and efficient inspections, enhancing safety and reducing operational costs.